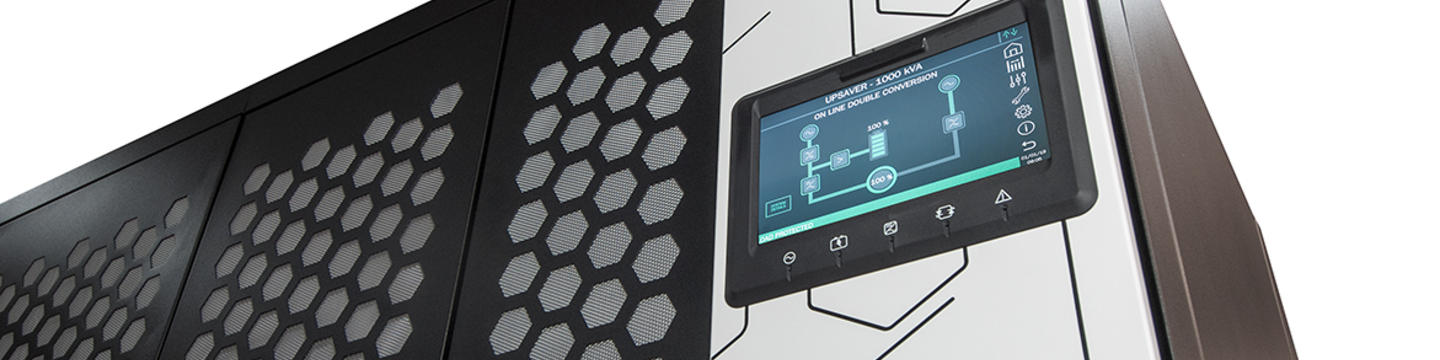

Why Proper UPS Sizing Is Crucial For Data Center Applications

Discover key considerations for choosing the right UPS for data centers, focusing on resiliency, adaptability, and cost efficiency.

Uninterruptible Power Supply (UPS) systems play a vital role in ensuring the continuous operation of data centers. However, selecting and sizing the right UPS for a data center's needs goes beyond power and battery capacity. In this article, we will explore the critical factors that data center managers need to consider when choosing a UPS system to meet the core needs of their data center.

Data centers have three primary needs:

- Resiliency: Data centers must ensure that their servers keep running, even in the face of problems and anomalies in the infrastructure. UPS systems are essential for providing this uninterrupted power supply.

- Adaptability: Data centers must frequently evolve and be upgraded quickly to meet changing demands and technologies.

- Cost Containment: Data center infrastructures consume substantial resources, including space and energy. Therefore, closely monitoring and controlling costs and energy consumption is crucial.

While UPS systems are primarily associated with the need for resiliency, their sizing can also have significant implications for adaptability and cost containment. Let's explore the main parameters to consider for selecting the right UPS:

Factors to consider when selecting the right UPS

A. Power calculation

To ensure an uninterrupted power supply, it's essential to determine the power of the UPS and the number of batteries needed to achieve the required backup time. To accurately size the UPS, it is essential to specify the nature and power rating of all the loads it will support. The nature of the loads is critical because it determines their power consumption characteristics, including inrush current, power factor, and any potential transient conditions that may affect UPS sizing.

In data centers, critical loads consist of two main categories: active loads and mechanical loads, with additional ancillary functions. Active loads include servers, storage devices, and electronic equipment used for data processing and communication. These are the backbone of the data center and demand the highest level of protection and availability from the power sources.

Mechanical loads encompass cooling systems and ventilation equipment, vital for maintaining the appropriate environmental conditions for the active loads. Additionally, there are ancillary functions such as lighting, emergency systems, safety measures, and surveillance.

Various factors, including the availability of backup diesel generators, load-shedding schemes, space and weight constraints, and budget considerations, typically determine the required backup time for the UPS. However, most data centers aim for a backup time of around 5 to 10 minutes, although longer autonomy periods of 30 minutes or more are also possible.

How to determine the appropriate power rating for the UPS

Electric loads consist of two components: Active Power, measured in Watts (W), and Reactive Power, measured in VAR (Volt Ampere Reactive). These components combine to form Apparent Power, measured in VA (Volt Ampere). Manufacturers of electronic devices typically specify the nominal Apparent Power absorption (VA rating), the Power Factor (PF), and sometimes the maximum input current of their equipment.

You can calculate Active and Reactive Power from the VA rating by taking the Power Factor into account using relevant electrotechnical formulas. In this article, the focus is primarily on determining the Watt rating: Active power in Watts (W) is calculated by multiplying the Apparent Power in VA by the Power Factor (PF). For example, a load rated at 100 kVA with a PF of 0.9 results in 90 kW.

Both pieces of information (VA rating and Power Factor) are essential for determining the required UPS power rating. UPS systems can provide power in VA within a specific range of power factors, which, in turn, corresponds to a specific range of available Watts.

The power factor of the loads and the backup time requirement are key factors to consider.

- Step 1: Collect all the power ratings of the supplied devices to find the overall VA need and then calculate the maximum active power (the Watts) for each. You can get the required total maximum active power by adding up the overall power.

- Step 2: Select a UPS that can provide the needed VA and Watts. For example, with a load totaling 100 kVA PF 0,9 (90 kW), the UPS must be sized at least to provide 100 kVA AND 90 kW.

Operating a UPS in overload mode can be problematic. While some UPS models can handle short and less intense overloads, exceeding the UPS's capacity can result in a switch to bypass mode, leading to a shutdown and load drop; but, if the upstream mains are not available with the UPS on battery mode, transferring to bypass will not be an option, and the UPS will shut down and consequently drop the load. For this reason, applying an oversizing factor is advisable: the advantage is having a power margin, ensuring the UPS will operate at less than 100% load percentage, thus preventing overload operation in case of load fluctuations (oversizing factors of 0.9 or even 0.8 typically offer a good design margin). Proper sizing, including a power margin, helps avoid overloads.

It's best practice to use independent UPS systems for different load categories in data centers; this ensures resilience, availability, and accurate design and sizing of the UPS units for each load type.

B. Battery autonomy

Once the power of the load is determined, batteries can be sized accordingly to have the desired autonomy (the time that the UPS can continue to feed their loads in case of a blackout).

Let's consider the example we gave earlier: we have a load with a maximum rating of 100 kVA at a PF of 0.9, resulting in 90 kW, and let's assume 10 minutes of autonomy is required. Let's further assume a 120 kW UPS will be operated (for instance, a UPS 120 kVA featuring a PF=1). For the battery sizing, we'll calculate it based on 10 minutes at a constant discharge rate of 90 kW, which is the actual load in Watts.

It's important to note that this calculation is theoretical. In practice, the 'real-life' autonomy of the batteries can be affected or shortened by various external factors and usage conditions, such as battery aging and ambient temperature. For this reason, a design margin can be applied by slightly oversizing the battery set to account for these potential variations; this helps compensate for both the aging of the batteries and the impact of thermal conditions. The related correction factors can typically be found in the technical literature for the specific batteries being used.

It's often the case that the maximum rated power of the infrastructure is determined during the design phase, allowing the UPS to be appropriately sized. However, the actual connected load within a data center can vary over time, either increasing or decreasing based on the center's operational needs. Given the critical need for high availability in data center applications, battery sizing is typically carried out with a worst-case scenario in mind, where the minimum autonomy is calculated based on the absolute maximum load. This approach ensures that under all possible load configurations, the system will always have at least the minimum required autonomy, even when the load reaches 100%.

How to decide on the correct autonomy time

The specific autonomy duration depends on the strategy, processes, and action plans in place to manage a blackout.

There are a couple of examples of blackout plans:

- In the event of a blackout, the UPS is designed to maintain power supply continuity until the Auxiliary Diesel Generator's output voltage stabilizes.

- Alternatively, in the case of a blackout, the UPS is set to ensure power supply continuity for the time required by the connected servers to execute an automatic controlled shutdown.

However, it's important to note that longer autonomy periods require larger battery sets, which can significantly impact the data center's physical footprint, weight, and overall costs. Additionally, batteries are considered "consumable items" and need to be regularly monitored, tested, and eventually replaced, making a substantial battery pack costly both in terms of capital expenditure (Capex) and operating expenditure (Opex).

Ultimately, the decision regarding the required autonomy is a trade-off between these various factors, considering the criticality of the data center's operations and the associated costs and maintenance considerations.

C. Selecting the correct performance and UPS architecture

UPS architecture can enhance data center needs in several ways:

- Redundancy: Parallel and modular architectures support redundancy (meaning you have more UPS units than the minimum required), ensuring continued operation even if one UPS or power module fails, improving reliability and availability.

- Scalability: These architectures allow for easy expansion, aligning with adaptability requirements. If the active load and power demand increase, simply add another UPS in parallel or other power modules. This feature is referred to as 'power on demand' or 'pay as you grow,' helping to optimize the Capex by 'buying power' only when required.

- Serviceability: Scalable and modular designs simplify installation and replacement, reducing operational costs. Other features like total front access, advanced diagnostic, user-friendly display, and remote monitoring can ensure additional savings on service and management costs.

Redundancy in the UPS

For instance, let’s consider again our previous example, a 120 kW UPS feeding a 90 kW load. If we connect in parallel to this single UPS another UPS of same model and power and with both of them, we feed the 90 kW load, we are in a typical case of 2N Redundancy (or 1+1 redundancy): if one of the two UPS fails, the other is enough to continue to feed the load. This means that our system is “1st failure proof”; that is it would need a second failure to drop the load and this is far less likely than one single failure.

In case of Modular UPS systems, it is even better, in fact power modules are like smaller UPS units connected in parallel with the others and the sum of their power will give the total power of the system. In our example, with 120 kVA-90 kW load, we might be choosing a 125 kW modular UPS, composed by 5 power modules, 25 kW each. In this case, to have redundancy, it is not needed to add a second same power UPS, but just add an additional power module. This means that the UPS will be composed by 5 modules to have the power plus one module for redundancy: this is called N+1 Redundancy (in this case N=5). If one module fails, the other 5 are enough to feed the load. Instead of deploying a complete UPS of the same power of the first unit we can use just one small module more and this is easier, faster, with less foot print and cheaper to buy and maintain.

Battery architecture

In addition to ensuring redundancy in the UPS, we have the option to use more batteries than strictly necessary, for example, by adding an extra set of batteries to achieve N+1 redundancy in the battery system. Furthermore, the architecture of the UPS plays a role in how batteries are deployed. Batteries can be either distributed or centralized. In a distributed battery setup, each UPS unit or power module has its own dedicated battery set. However, in a centralized battery setup, the same battery set is connected to the entire UPS system. In distributed battery architectures, if we have a redundant UPS or module, we would also need a corresponding redundant battery set. In contrast, in centralized battery architectures, it is possible to achieve power redundancy without the need for battery redundancy. The choice between these two approaches depends on the preferences and requirements of the designer.

D. Energy consumption and efficiency

UPS units, like all electrical devices, consume energy, which means that when you add a UPS to your system, it increases your overall energy consumption.

To measure how efficiently a UPS uses this energy, we use a parameter known as "Energy Efficiency." Efficiency is defined as the ratio of Output Power divided by Input Power. This value is always less than 1 (or 100%). The difference between the input power and the output power represents the energy that is converted into heat inside the UPS. It accounts for the overall energy the UPS requires to operate its internal converters, electronic circuits, batteries, and more. In simpler terms, it's the energy the UPS needs to fulfill its role in protecting critical loads.

It's possible to disable some of the converters and supply the raw mains power to the loads via the UPS static bypass. This operation mode is often referred to as "ECO Mode" or "Offline Mode," depending on how extensively the converters are disabled. In these cases, efficiency increases, but at the same time, the degree of load protection decreases. The highest level of protection offered by the UPS is achieved when the entire UPS system is operational, which, of course, results in maximum energy consumption.

Any operational mode other than pure Online Double Conversion offers a lower level of protection against issues with the quality of the mains power. Eco mode, offline mode, and even line-interactive modes allow many mains power quality problems to pass through to the connected equipment, potentially leading to premature wear or damage. However, these modes do ensure a continuous power supply because if the mains power quality deteriorates beyond a certain predefined tolerance, the UPS will smoothly switch to inverter mode. On the other hand, when the UPS operates in Online Double Conversion mode, the level of protection is consistently at its highest; this is because the inverter generates a pure sine wave continuously, and no transition is required.

Eco modes were originally developed to provide higher efficiency at a time when Online Double Conversion was implemented using less efficient technology. Nowadays, advancements in efficiency have been achieved, even at low load levels. As a result, there is less need for Eco mode operation. Nevertheless, data center managers still have the flexibility to implement mixed-mode strategies, enabling them to strike the right balance between efficiency and protection. Eco mode is particularly useful in temporary situations, such as when the critical load is reduced during maintenance or upgrades, and the UPS operates at a low load to protect auxiliary devices. In such cases, the Online efficiency might fall significantly below its nominal rating, and Eco mode can help reduce energy consumption.

Impact on energy savings

UPS systems can be designed and manufactured to deliver high performance and efficiency. A well-designed, properly configured, and suitably sized UPS can maintain a high level of efficiency even when it's not operating at its maximum load capacity. However, it's important to note that UPS efficiency decreases as the power load decreases.

When selecting a UPS, it's crucial to consider its efficiency not only at nominal power but also at lower power loads; this is especially vital when the UPS will be used in redundant setups where it might operate at load levels as low as 30%.

For instance, in a Parallel Redundant configuration used to enhance system availability, efficiency can suffer since it involves utilizing twice the amount of electronic components to power the system at half the load. In such scenarios, a UPS system with a high-efficiency level at load percentages lower than 50% is the preferred choice. This is why in redundant configurations, Modular Architecture is often the favored option because it excels at maintaining high efficiency due to the flexibility of its power modules and the implementation of techniques for automatic power adjustment.

Efficiency can also be enhanced through advanced battery charge management systems. It's worth noting that all energy losses in a UPS are released into the environment as heat, which must then be managed by cooling systems, resulting in additional energy consumption.

What’s the best UPS choice for your data center needs?

Many power continuity applications can accommodate basic UPS models with lower efficiency or longer service intervention times. However, data centers have stringent requirements, and the critical nature of these applications justifies investing in premium solutions. Additionally, the investment in premium solutions can lead to Total Cost of Ownership (TCO) optimization. Over the operational lifespan, these investments can be recovered through savings in electricity costs, reduced maintenance, space utilization, and power upgrades.

Thanks to energy and management savings, it's possible to recover a portion of the investment. In some cases, even a slight difference in efficiency can lead to the entire investment being recouped over the UPS's operational life, thanks to energy savings. Particularly at high power levels, even a small difference in efficiency can result in a significant reduction in energy consumption. For instance, consider two 1 MW UPS units operating at 75% load: UPS 1 with 97% efficiency and UPS 2 with 96% efficiency. By using UPS 1 instead of UPS 2, you can achieve an impressive 80 MWh per year in electric energy savings, thanks to the 1% higher efficiency of UPS 1 (this calculation also accounts for energy savings in the cooling system).

When it comes to choosing the right UPS for a data center, it's not just about power and autonomy. Data center managers need to follow a structured approach. First, it's important to understand the nature and power requirements of the load to be protected. Next, determine the required autonomy time to size the battery system appropriately. Finally, evaluate the other electrical system components surrounding the UPS, such as transformers, generators, Automatic Transfer Switches (ATS), Static Transfer Switches (STS), and more.

We are here to provide comprehensive support. We offer tools, guides, and expertise to assist in identifying the best solution. We can provide training, documentation, software, and personal consultations with product specialists to help customers understand their needs and explore potential actions. Moreover, after selecting the UPS, we can offer hands-on experiences with the actual product, including training, demonstrations, Factory Acceptance Testing (FAT), Site Acceptance Testing (SAT), and more, to ensure that all the details of the chosen solution meet the specific requirements.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand